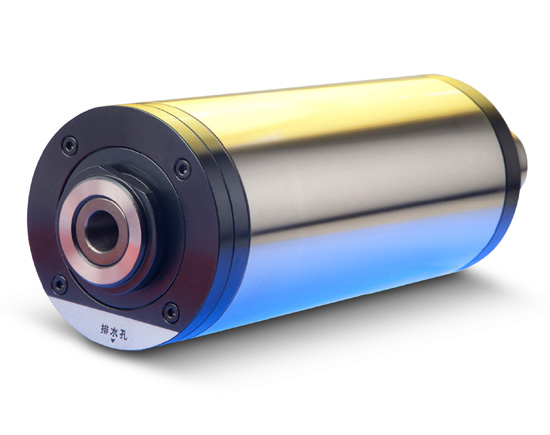

High Speed Grinding Spindles

10,000~50,000 r.p.m.

With decades of grinding wheel spindles manufacturing

experiences, we continue to invest in new technology to

ensure the spindles are rigid, efficient and outstanding.

| r.p.m | 8,000 r.p.m | 10,000~30,000 r.p.m | 40,000~50,000 r.p.m |

|---|---|---|---|

| Bearing Material | Steel ball | Steel ball | Ceramic ball |

| Bearing Lubrication | Grease | Grease | Grease |

| Transmission | Belt | Belt | Belt |

| Taper Deflection | 0.002mm | 0.002mm | 0.002mm |

| Test Bar Deflection | 0.003mm | 0.003mm | 0.003mm |

| Installation | Horizontal | Horizontal | Horizontal |

| Diameter | 90mm | 90mm | 90mm |

| Weight | 15.9Kgs | 11Kgs | 11Kgs |

Rigid, Efficient and Outstanding

--Grinding wheel spindles (belt type) are available.

--Every spindle undergoes a rigorous inspection to ensure

the quality of the product.

--The patented waterproof design extend the life of grinding

wheel spindles.

--With decades of grinding wheel spindles manufacturing

experiences, we continue to invest in new technology to

ensure the spindles are rigid, efficient and outstanding.