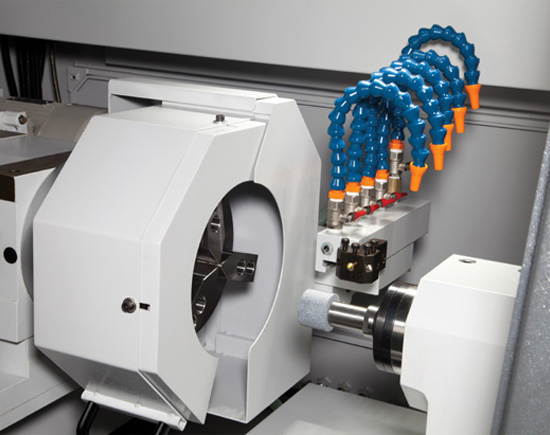

CNC Internal Grinder (Full Cover/Semi Cover)

S10-F

| Swivel over table dia. | Ø400mm |

|---|---|

| Workhead Speed | 0-1000r.p.m |

| Workhead swivel by manual | +15º & -5º |

| X-axis max. travel | 200mm |

| Z-axis max. travel | 330+200mm |

| Grinding capacity | Ø2~300mm |

| Max. grinding diameter | Ø60mm |

| Max. grinding depth | 200mm |

| Max. grinding faces | 8 |

| Max. workpiece weight | 45kgs |

| X-axis speed | 0~10000mm/min |

| Z-axis speed | 0~10000mm/min |

| X-axis min. travel unit | 0.0001mm |

| Z-axis min. travel unit | 0.0001mm |

| Workhead motor | 1.5 kw, 4p |

| Z-axis grinding wheel motor | 2.2 kw, 2p |

| Electricity requirement | 10 kw |

| Machine Dimensions | 2300(W) x 1350(D) x 1810(H)mm |

| Space requirement for installation | 3370(W) x 2250(D) x 2410(H)mm |

| Machine weight | 3000 kgs |

Multiple Faces Grinding

Equipped with "FANUC" CNC control system for grinding

"ID," "end face," and "taper" up to 8 different faces in ONE

clamping.

Digitized Internal Grinder

In response to the digitized operation in the machine industry,

our CNC and NC internal grinders are equipped with advanced

computer numerical control system. Compared to conventional

hydraulic internal grinder, our CNC and NC type grinders have

higher stability and accuracy, making it suitable for a mass and

automation production.

Solid Body Structure

The structure of the machine has a solid base consists of high

density cast iron, enabling precise performance. Due to its

sturdy design, damages to the machine can be avoided.

Uniaxial Movement

The utilization of axial movement is revolutionary compared to

the conventional method using the cross stacking movement.

To avoid deviation caused by the vibration of mechanical

movements can endure stability and precision during the

grinding process.